Samhita Technologies is offering Distributed Control Systems for continuous or batch process industries to operate form collaborative control rooms

Our offering

-

AC 800M controller designed for process industry. With Memory selection range form 12MB to 256MB and Operation Performance form 0.46 ms to 0.09 ms, Redundancy & Hot Swap is supported.

- Modular and flexible for all environments,ready for future expansions

- Robust design and redundancy options in all critical areas of the controller and its components eliminates single-point failures and secures maximum availability

- Supporting standard IEC 61131-3 programming languages

- Rich function block library includes several types of control loops, including advanced control and auto- tune capabilities

- All Standards for optimum communication connectivity such as Ethernet, PROFIBUS DP, etc.

- Integration for ABB drives over optical ModuleBus port

- OPC (Open Platform Communications) server connectivity with ABB & third party SCADA system.

-

AC 800 S800 I/O- open process I/O system, offers from standard function to high end features like hot-swap, HART, time tagging, redundancy down to I/O channel.

- S800 I/O is an open comprehensive, distributed, process I/O system that communicates with AC800 series controllers by direct connection or over industry-standard field buses.

- Suitable for installation in the field, close to sensors and actuators, it reduces cabling cost.

- field device interfacing, from basic analog and digital I/O, as well as intrinsic safety and high integrity solutions.

- Comprehensive diagnostics, hot swapping of modules and redundancy solutions

- Standard field bus PROFIBUS DP, compatible also with non-ABB controllers.

- Highly modular and can be built in a near infinite number of ways, from highly centralized to highly distributed.

- S800L remote I/O are compatible with S800 I/O modules

- S800L remote I/O with robust mechanics, one-piece handling, easy mounting and smart connections directly to the AC 800M or via a cost-efficient fiber optic extension, With the GSD file, S800L I/O can be used with any control system.

-

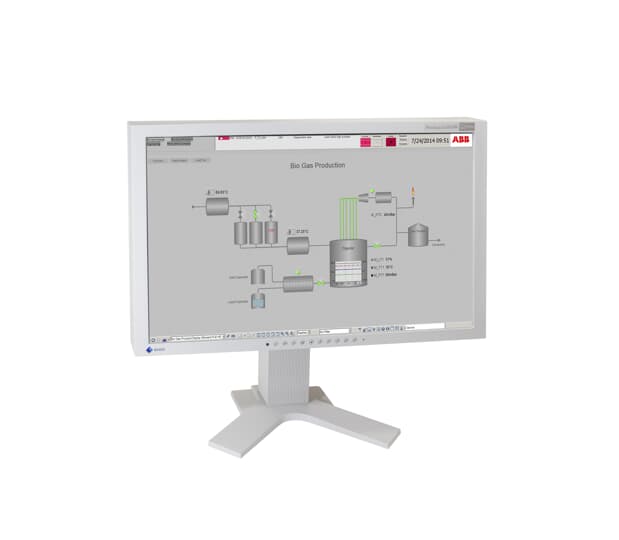

Compact HMI: A scalable PC based SCADA system for real-time operation and process control. Basic Software us with 1 Server Workplace and 1 Smart Client Workplace, additional 10 Smart Client Workplace can be added as per requirement.

- Compact HMI directly interface to a large number of OPC-compliant controllers and it’s built in drivers can connect to major PLCs.

- High performance pre-fabricated, re-usable graphics library based on industry best-practice principles to help quick creation and utilization of graphic displays.

- Embedded CAD Viewer for object centric CAD drawings.

- Smart Client for intelligent data access and viewing to facilitate in making quick, informed decisions and improving performance

- Flexible alarm management with alarm shelving and alarm analysis for convenient alarm monitor and analysis

- Real-time notification of alarms via email or SMS

- Compact HMI Option Packs

- Server Workplace Size 50 Signals (20 Tags), Client Workplace Size ≤ 200 Signals

- Server Workplace Size 500 Signals (200 Tags), Client Workplace Size ≤ 500 Signals

- Server Workplace Size 2500 Signals (1000 Tags), Client Workplace Size ≤ 1000,2500,5000 or 10,000 Signals

-

System 800xA is not only a DCS (Distributed Control System) it’s also an Electrical Control System, a Safety system and a collaboration enabler with the capacity to improve engineering efficiency, operator performance and asset utilization.

- Efficient Engineering.

- Process Control, Electrical & Safety Integration in one system .

- Flexible I/O solutions.

- Increased flexibility and scalability.

- IEC 61850 Edition 2 brings engineering efficiency.

- Enabling collaborative operations.

-

Samhita Technologies provides control room connectivity packages with ready-made object types for a wide range of systems. They include graphic elements, faceplates, alarm and event handling etc. .

- Control systems connectivity and modernization.

- Enabling control rooms consolidation with one HMI.

- Fewer operator responsible for more interconnected processes.

- Samhita Technologies unique capabilities of true control room consolidation.

- Improves Operator Effectiveness.

- Efficient Engineering Environment.

- Ergonomic furniture and control centers specially designed with the operators in focus drive productivity, quality and safety to new levels.